Suitable compressors for a Greener Planet

Widespread awareness campaigns and increasingly stringent regulations encourage virtuous acts of sustainability. In EU countries, the reference standard on environmental sustainability for equipment that makes direct or indirect use of energy is the Ecodesign Directive. Particularly in the HVAC/R sector, the requirement is not only dictated by regulatory references but also by the market's own demands, given the new political-economic scenario that has emerged since the conflict in Ukraine.

Conscious compliance with these requirements implies optimising the performance efficiency of equipment, thus reducing operating costs. The areas of application vary, from heat pumps, to process chillers and refrigeration in general, etc. And for each specific use, it is a question of finding the most sustainable, reliable and affordable solution.

CAREL brings to life virtuous sustainability and finds its most “natural” expression in identifying and proposing the most suitable solutions for each application area and market.

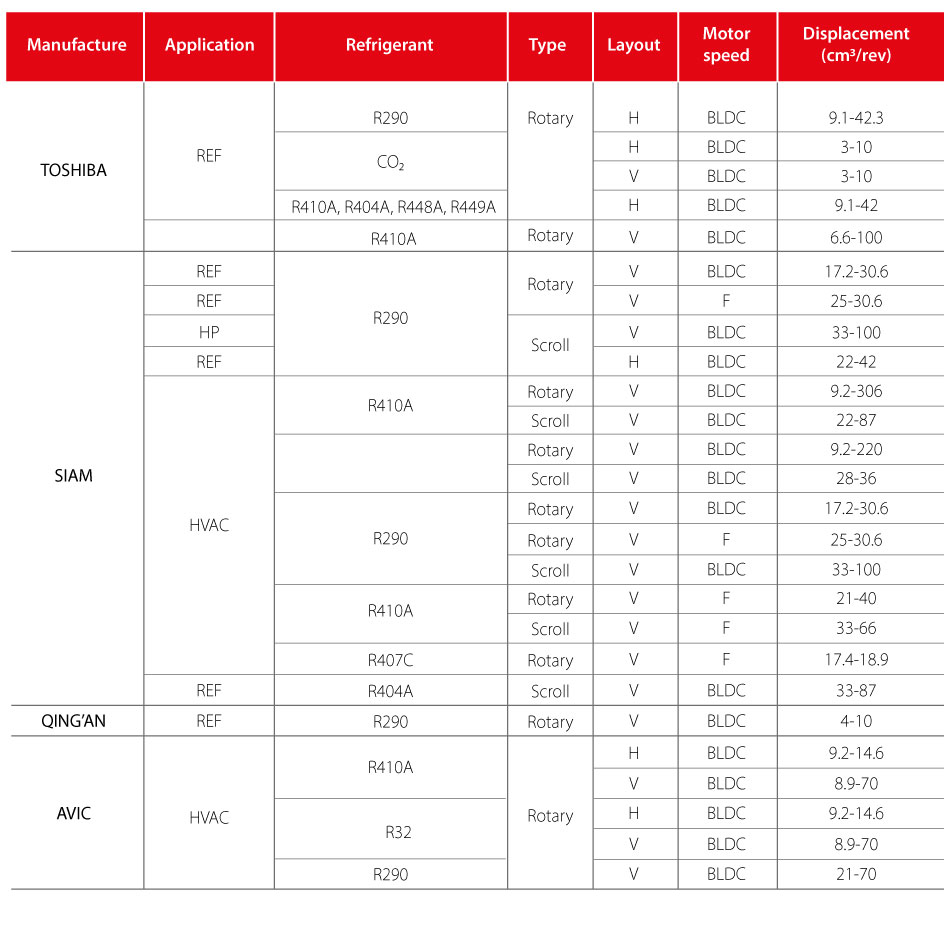

This study and years of experience in control systems and continuous experimentation have led to the choice of the range of scroll and rotary compressors available today in the CAREL product range. Alongside the more traditional ranges for the use of synthetic refrigerants (R-410A, R-32, R-448A, R-449A, etc.) are those designed for natural refrigerants, also focused on environmental sustainability as they have low or zero GWP. These include carbon dioxide (R-744, CO2) and propane (R-290).

They range from fixed-speed compressors to variable-speed compressors, which use BLDC technology with a DC inverter. Depending on the application, the variability of the load and the working conditions in general, the two solutions may be used as alternatives or in synergy. But it goes without saying that the most common situations, and therefore worthy of greater attention, involve the variability of load and working conditions. It is precisely for these that CAREL has developed particularly efficient products and solutions. In fact, inverter BLDC technology with a DC inverter combined with the adoption of the electronic expansion valve allow for large, precise and always energy-efficient capacity modulation.