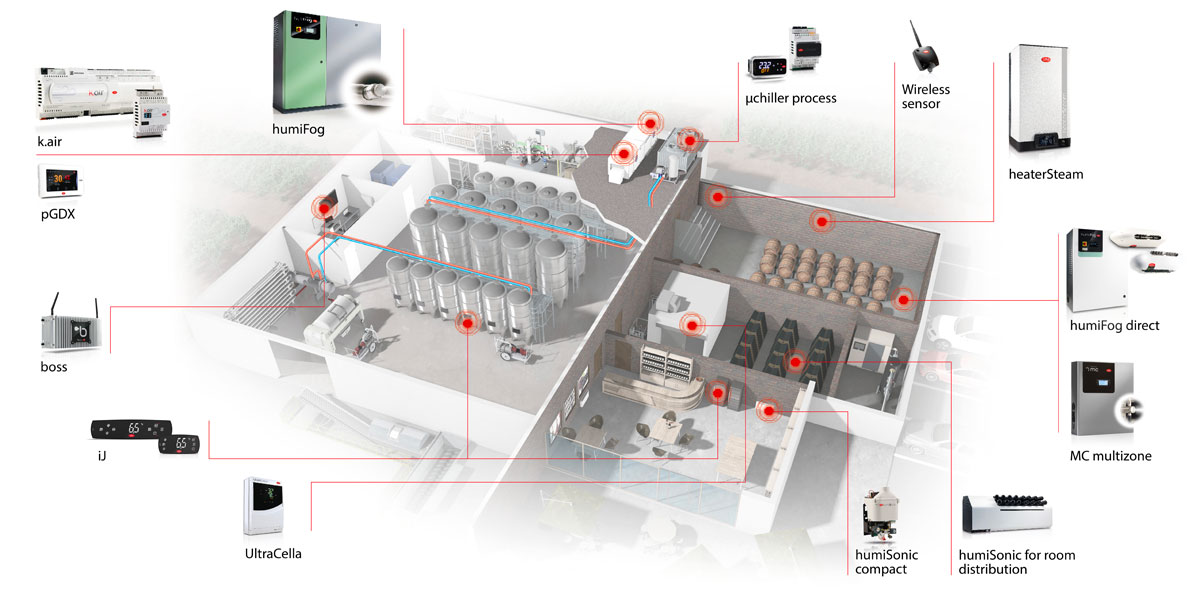

k.Air

General characteristics

k.Air is the ready-to-use solution for managing air handling and ventilation units.

k.Air is a preprogrammed and fully-configurable controller, designed to reduce times and costs, from design right through to commissioning. Thanks to the LARGE, MINI, and SMART versions and the feature-rich software, k.Air offers considerable flexibility, so as manage as many applications as possible, from the simplest to the most complex unit.

The distinctive feature of k.Air is the result of CAREL's extensive experience in air handling unit and humidification management applications. Its intelligent control logic in fact ensures comfort, indoor air quality and a healthy environment, always with the lowest energy consumption, through hygienic and efficient operation of all of the components of the air handling unit.

k.Air offers an advanced user experience: simplified access to information for users and service via an integrated web interface. A set of graphic pages with unit dashboards are available from first start-up, ready to be used with the new pGDx family of touchscreen displays.

-

Plus

Flexibility

A single application with modular architecture, designed to adapt to a wide range of application layouts.

Plug&play

Easy configuration and commissioning.

- Pre-loaded configurations;

- Custom configurations generated by an external tool;

- Auto-Backup of the last active configuration;

- Manual configuration via display of all the unit's components;

Connectivity

Simplified integration, both in the field with the unit's components, and integration with higher-level supervisory systems or BMS via built-in serial and Ethernet communication. Standard building automation protocols such as Modbus and BACnet are native in the controller.

Usability

Built-in web interface with graphic pages and dashboards.

Air quality and hygiene

- Indoor air quality control

- Accurate control of isothermal and adiabatic humidification

- VDI-6022 program, with functions to improve unit hygiene based on the requirements of the VDI standard

Energy efficiency

- Smart device management based on minimum energy consumption

- Freecooling, freeheating, heat recovery and indirect evaporative cooling

- Management of direct expansion systems with DC compressors and EEV synchronisation