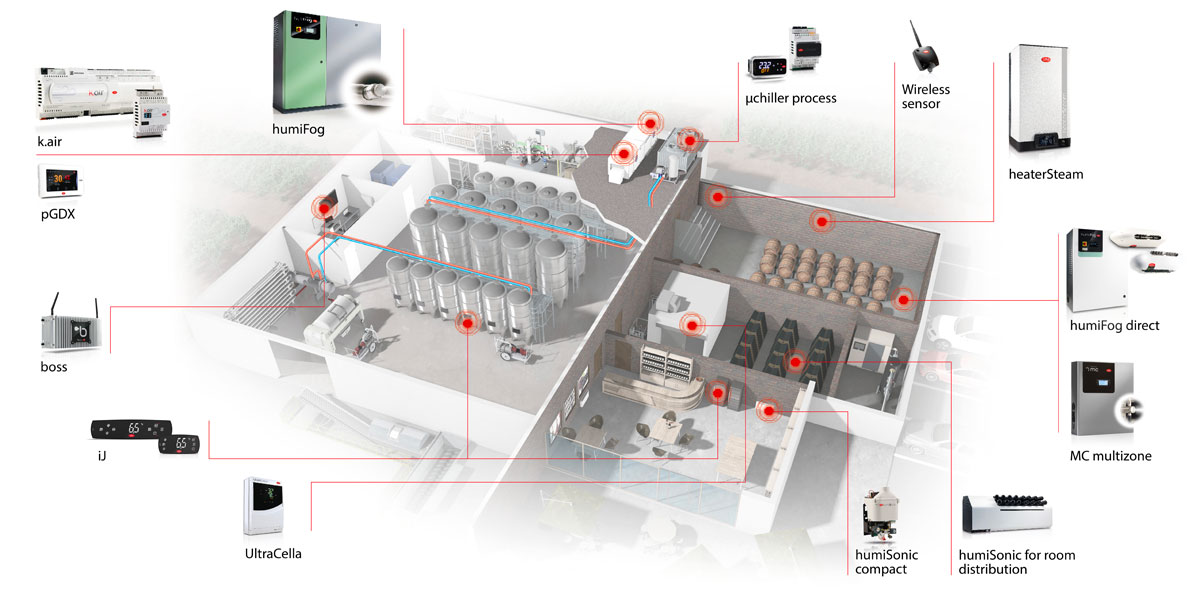

- System solutions

- Agricultural and Food Industry

- Air-conditioning in commercial applications

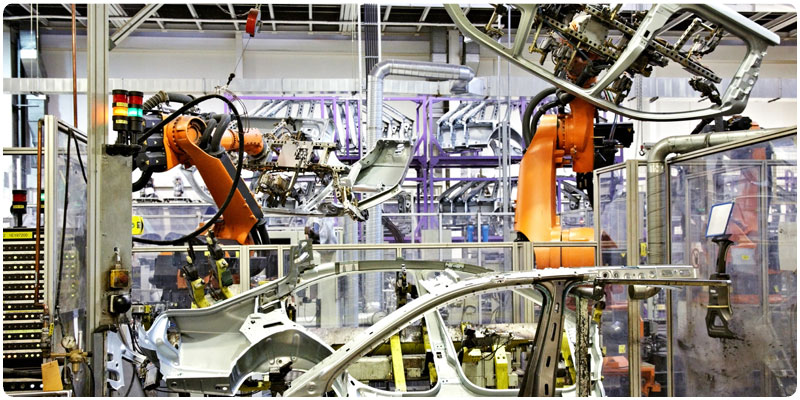

- Automotive

- Cleanrooms

- Convenience store

- Cultivation of mushrooms

- Data Center

- Die Casting

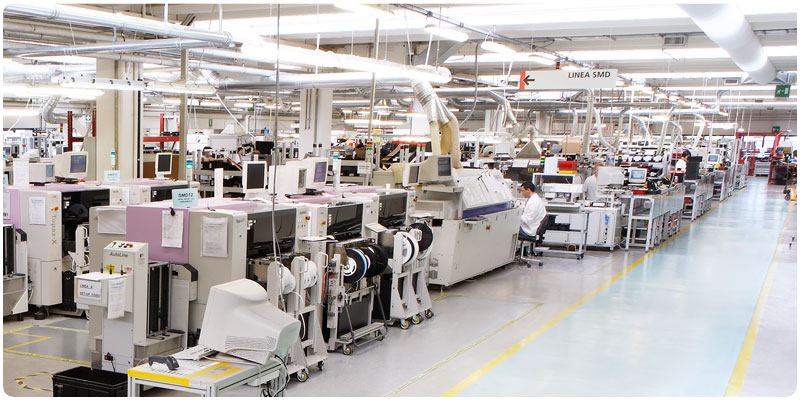

- Electronics and Hi-tech industries

- Evap. cooling for chillers and drycoolers

- Evaporative cooling for AHUs

- Hospitals and Operating Rooms

- Hotels

- Hypermarket

- Industry and Process

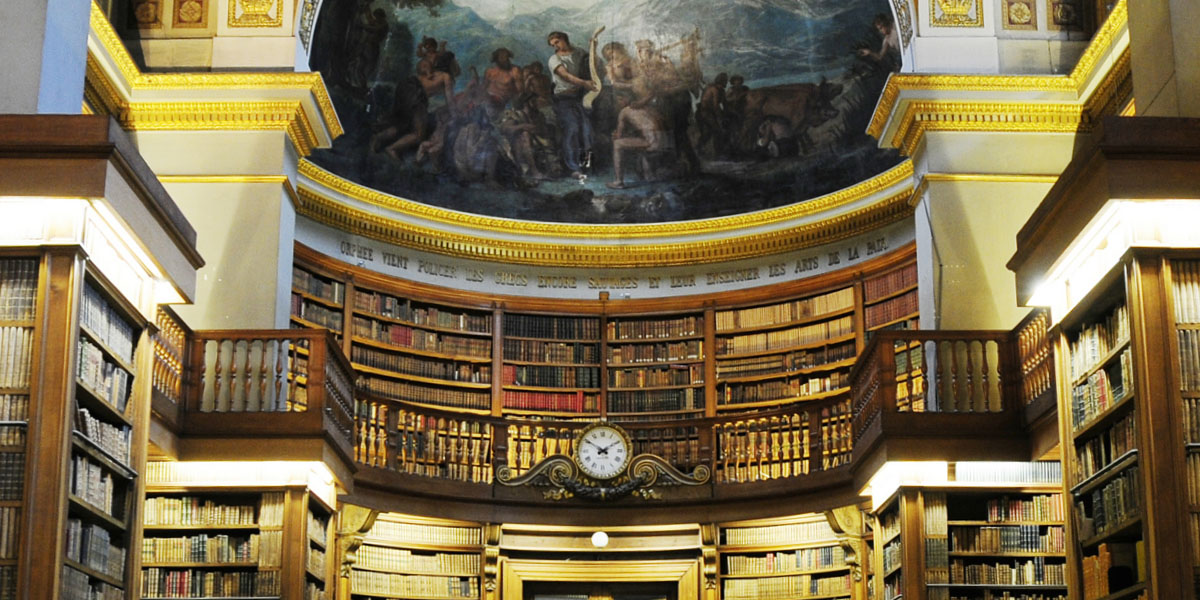

- Museums, Libraries and Theatres

- Offices

- Painting and coating

- Pharmaceutical industry

- Plastic Industry

- Printing industry

- Production of bread and rusks (crisp bread)

- Remote operation centre

- Residential

- Restaurant chain

- Shopping centres

- Steam baths and Spas

- Textile industry

- Tobacco Industries

- Wine industry

- Wood industry

- Unit control

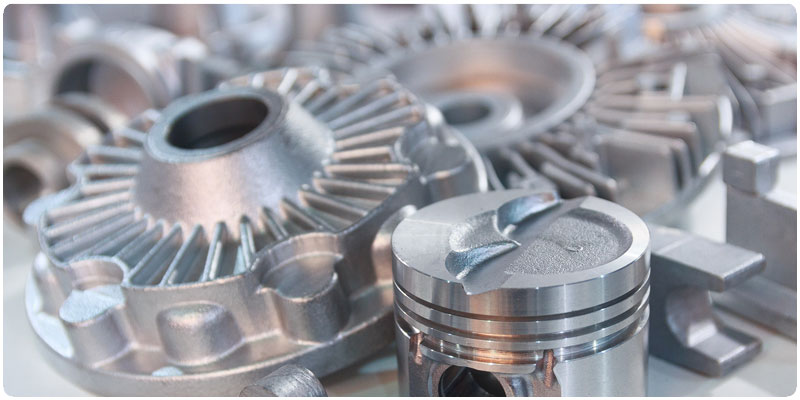

Die Casting

-

General characteristics

Die casting is a manufacturing process that can produce metal parts through the use of reusable molds, called dies. The die casting process involves the use of a furnace, metal, die casting machine, die and all the auxiliary equipment to keep all of them at the right temperature. The metal, typically a non-ferrous alloy such as aluminum or zinc or copper or magnesium, is melted in the furnace and then injected into the dies in the die casting machine. At the beginning of the cycle, dies require heating to the optimum temperature for the casting process, typically around 200ºC.

As the process takes place, molten alloys at temperatures of up to 700ºC will heat up the die.

If the die temperature is not appropriate, both at initial heating and following cooling phase of the die, troubles such as breaking, damage or malfunction of die and finished product may be caused.

In order to keep die always at right temperature, several Temperature Control Units (TCU’s) are used.

-

Discover related products

-

0 to 5 V ratiometric - SPKT*R* NA

-

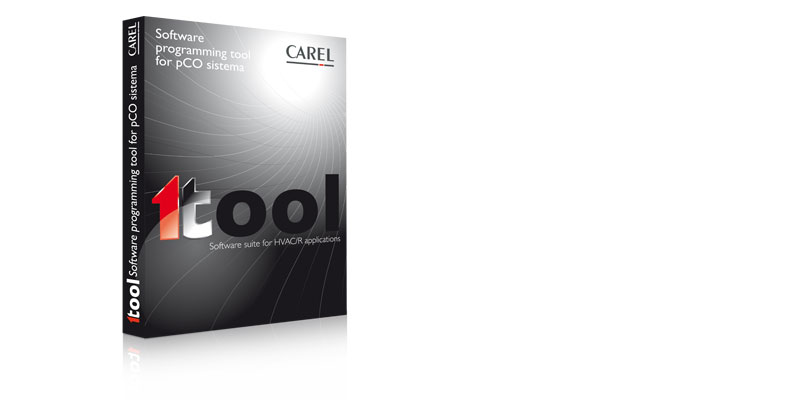

1tool

-

4 to 20 mA - SPKT*C*

-

Antifreeze thermostat

-

Bluetooth GATEWAY for apps

-

boss one

-

c.pCO

-

c.pCO mini

-

chillBooster

-

Clima

-

Cloudgate

-

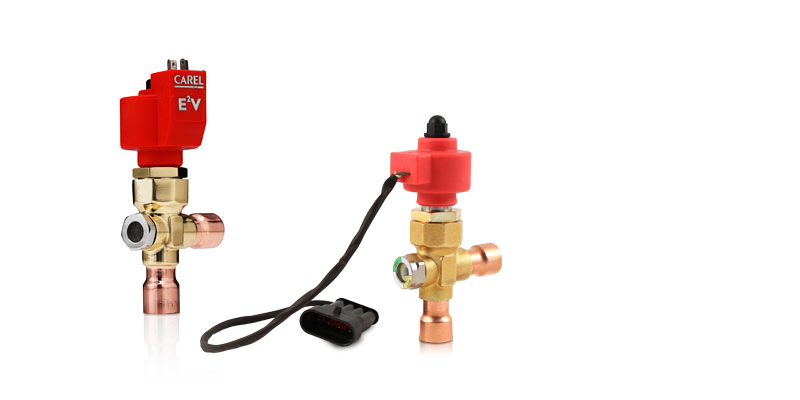

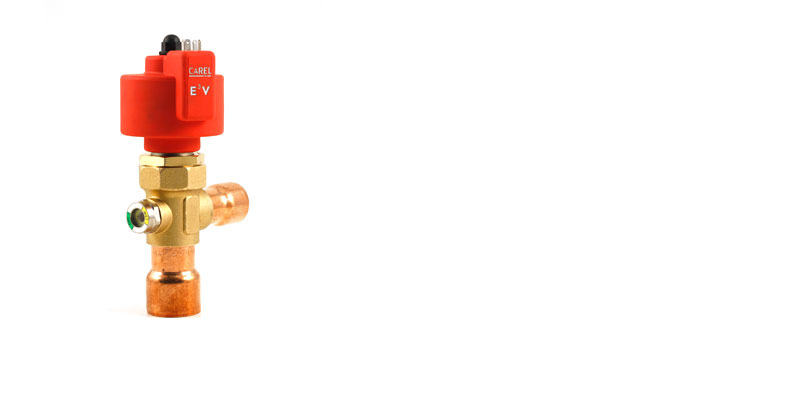

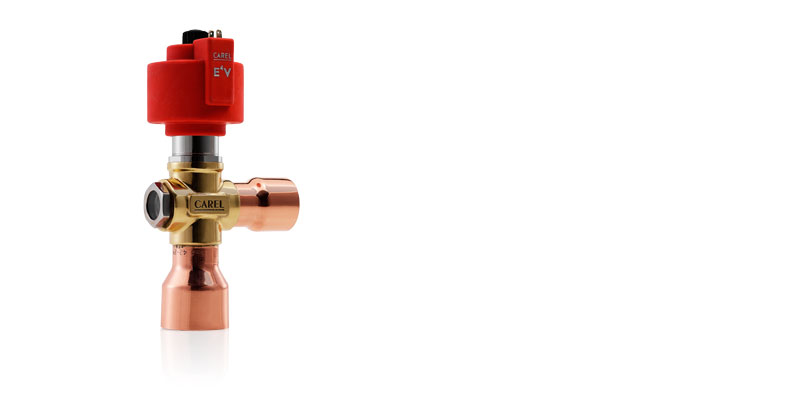

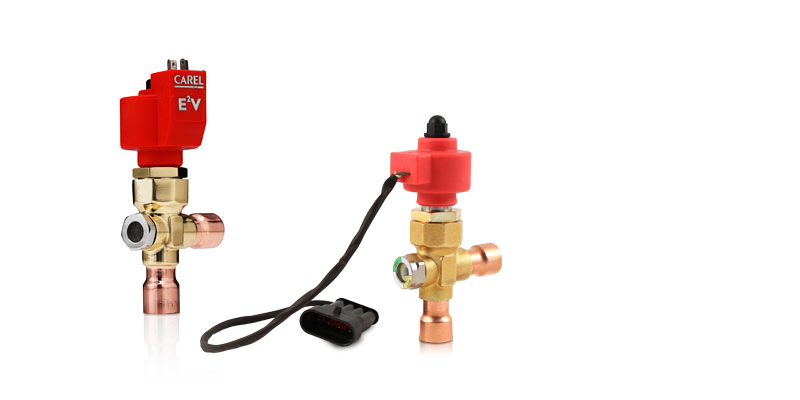

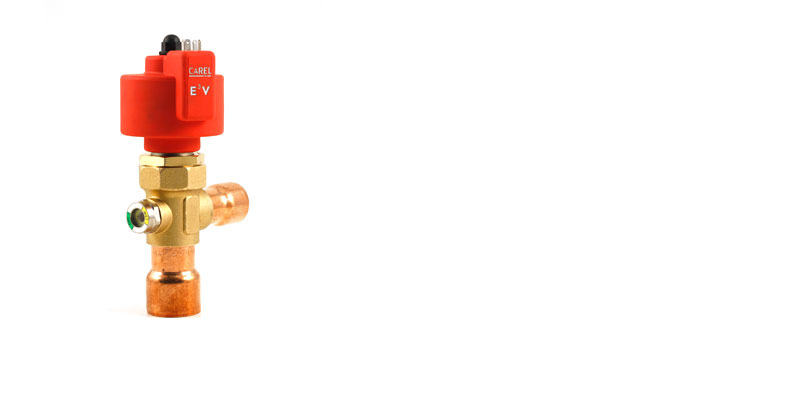

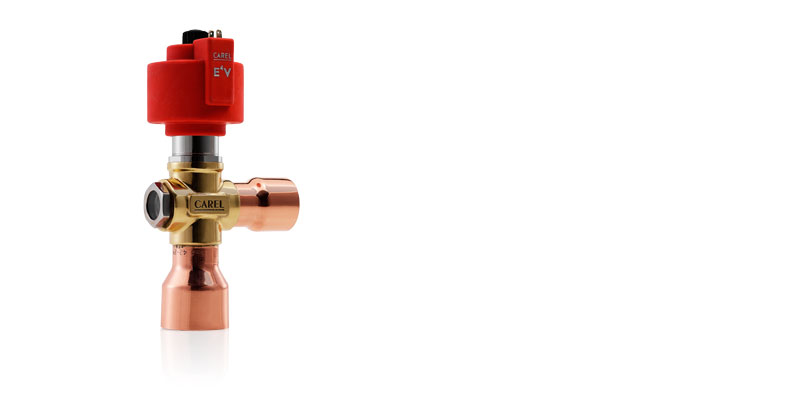

E2V - Z (demountable)

-

E2V fully welded

-

E3V - B (hermetic)

-

E3V - S (demountable)

-

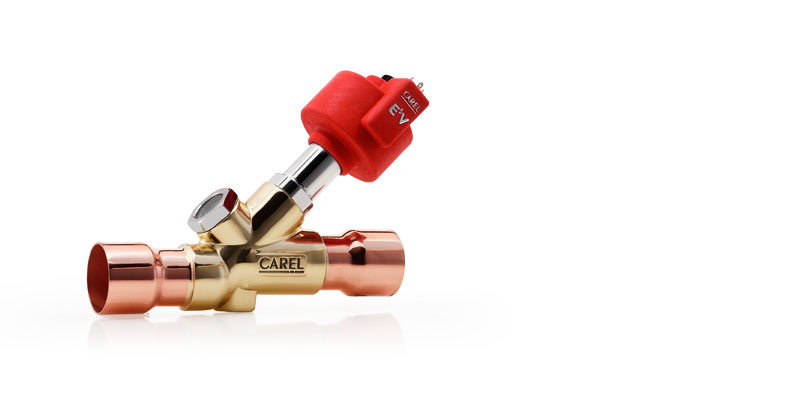

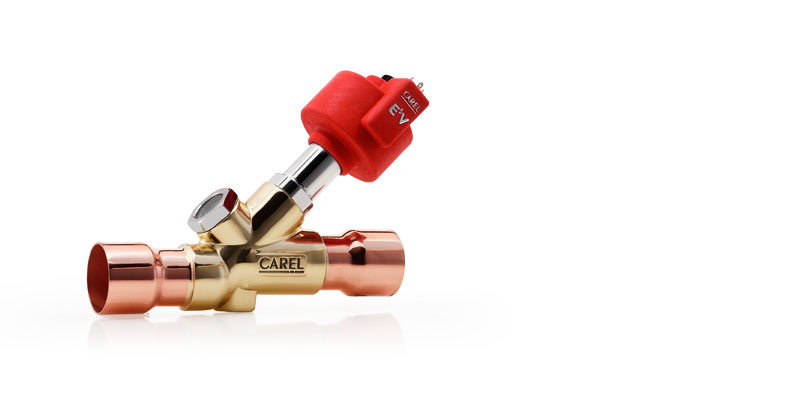

E4V

-

E5V

-

E6V

-

E7V

-

easy way

-

EVD Evolution Twin

-

GLD Small

-

ir33 universale

-

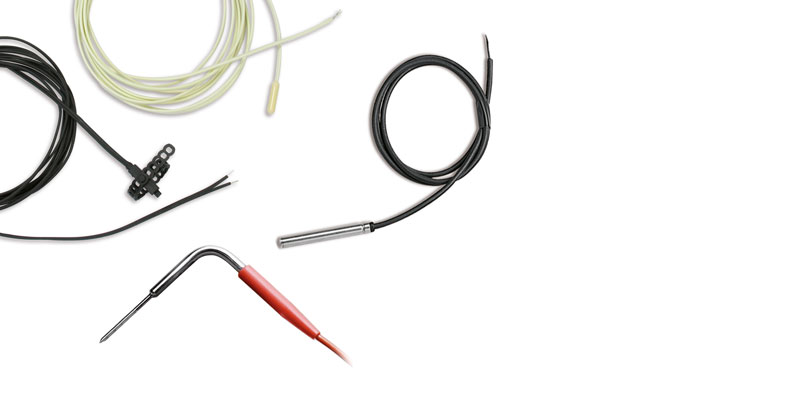

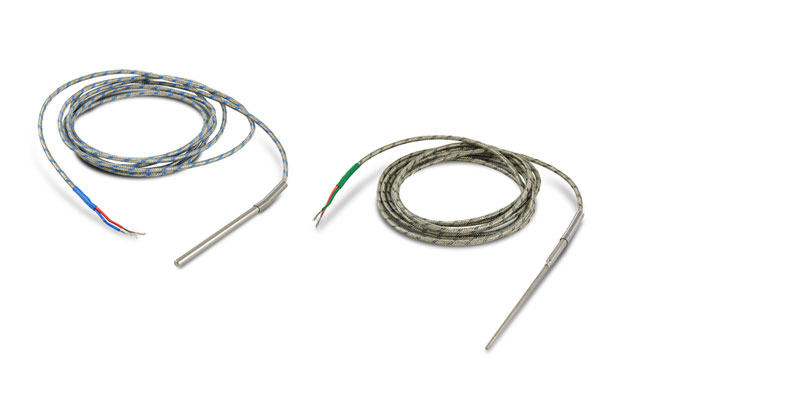

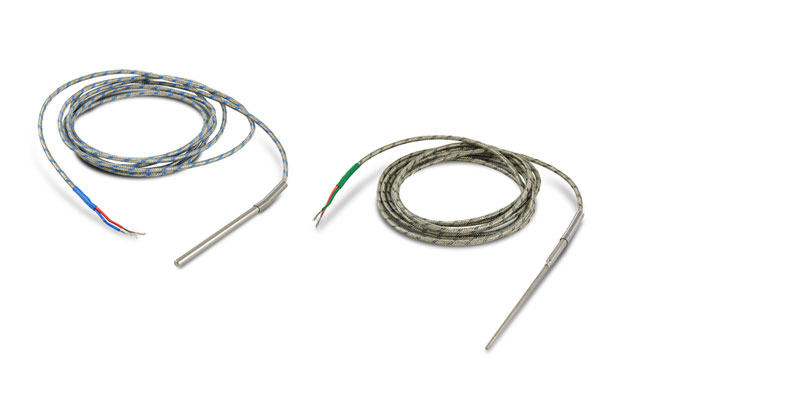

J and K thermocouples

-

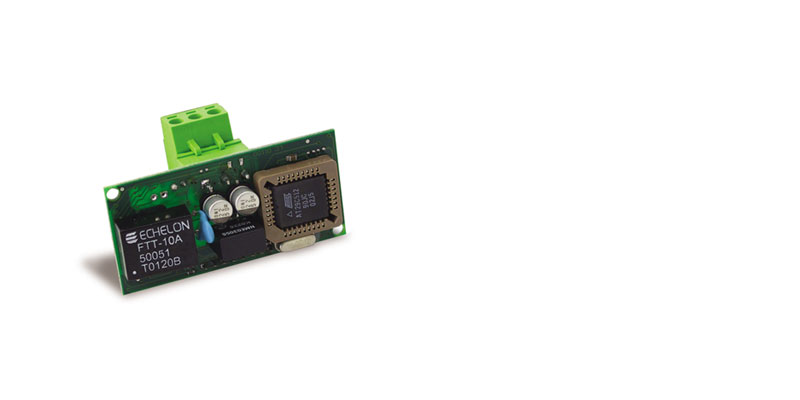

LONWORKS card NA

-

NTC

-

NXL variable frequency drive

-

pAD

-

pCO5+

-

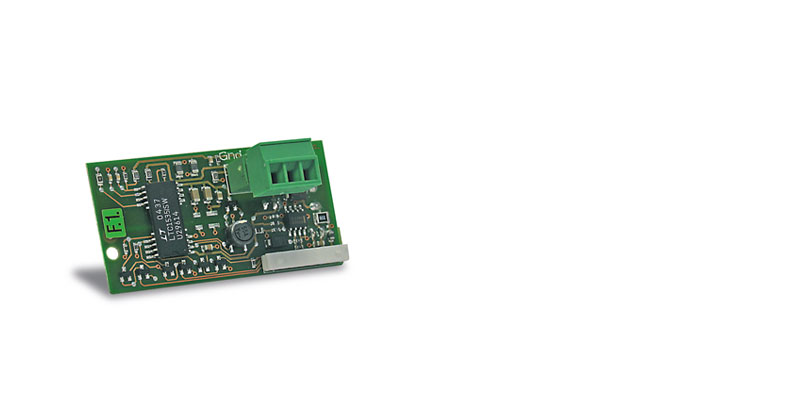

pCONet card

-

pCONet SE card

-

pCOWeb card

-

pCOWeb SE card

-

pGD Touch NA

-

pGD1 / pGDe

-

pGDX

-

Phase sequence controller (RSF)

-

PlantVisorPRO

-

PlantWatchPRO

-

pLDPRO

-

power+

-

PT1000

-

Ratiometric pressure sensors - SPKT*P0

-

Ratiometric pressure trasducers - SPKT*S0

-

Ratiometric trasducers welded version - SPKS*

-

RemotePRO

-

RS485 card

-

RS485 card- FieldBus

-

Series three-phase fan speed controller

-

single-phase

-

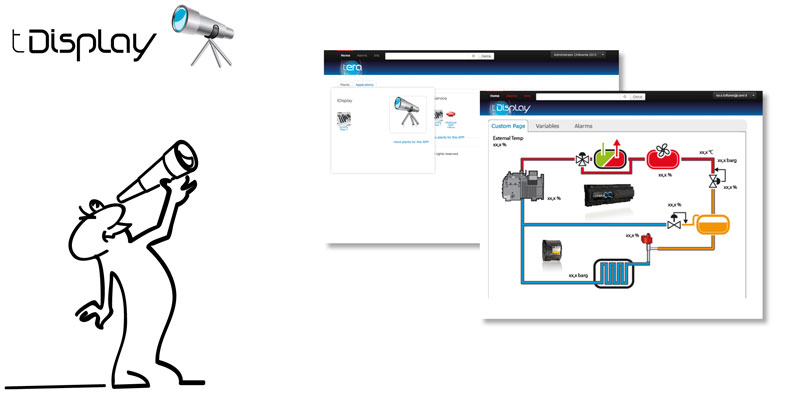

tDisplay

-

three-phase (IP55)

-

three-phase (IP55) with RS485

-

tService

-

Ultracap

-

Variable Frequency Drive

-

Wi-Fi GATEWAY for boss applications

-

µC2 SE NA

-

0 to 5 V ratiometric - SPKT*R* NA

-

1tool

-

4 to 20 mA - SPKT*C*

-

Antifreeze thermostat

-

Bluetooth GATEWAY for apps

-

boss one

-

c.pCO

-

c.pCO mini

-

chillBooster

-

Clima

-

Cloudgate

-

E2V - Z (demountable)

-

E2V fully welded

-

E3V - B (hermetic)

-

E3V - S (demountable)

-

E4V

-

E5V

-

E6V

-

E7V

-

easy way

-

EVD Evolution Twin

-

GLD Small

-

ir33 universale

-

J and K thermocouples

-

LONWORKS card NA

-

NTC

-

NXL variable frequency drive

-

pAD

-

pCO5+

-

pCONet card

-

pCONet SE card

-

pCOWeb card

-

pCOWeb SE card

-

pGD Touch NA

-

pGD1 / pGDe

-

pGDX

-

Phase sequence controller (RSF)

-

PlantVisorPRO

-

PlantWatchPRO

-

pLDPRO

-

power+

-

PT1000

-

Ratiometric pressure sensors - SPKT*P0

-

Ratiometric pressure trasducers - SPKT*S0

-

Ratiometric trasducers welded version - SPKS*

-

RemotePRO

-

RS485 card

-

RS485 card- FieldBus

-

Series three-phase fan speed controller

-

single-phase

-

tDisplay

-

three-phase (IP55)

-

three-phase (IP55) with RS485

-

tService

-

Ultracap

-

Variable Frequency Drive

-

Wi-Fi GATEWAY for boss applications

-

µC2 SE NA

-

-

Discover related unit control applications