- System solutions

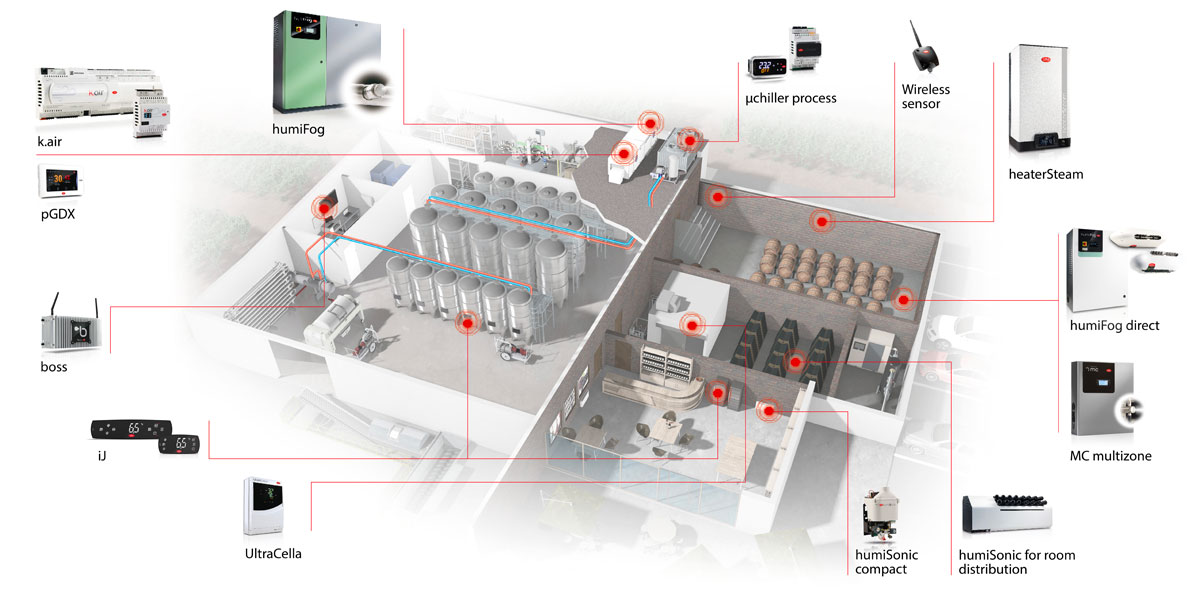

- Agricultural and Food Industry

- Air-conditioning in commercial applications

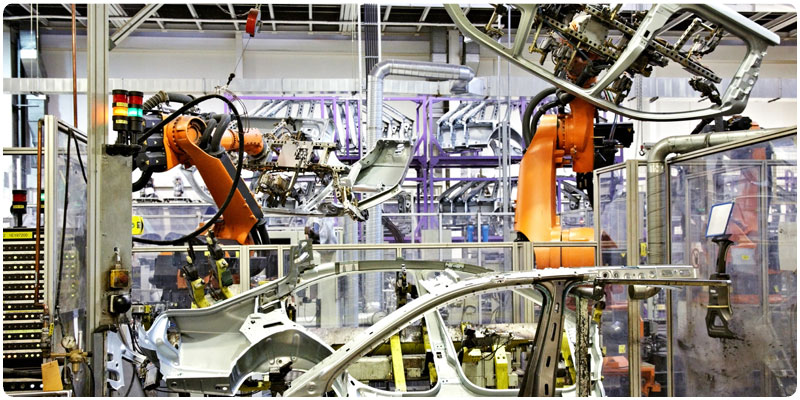

- Automotive

- Cleanrooms

- Convenience store

- Cultivation of mushrooms

- Data Center

- Die Casting

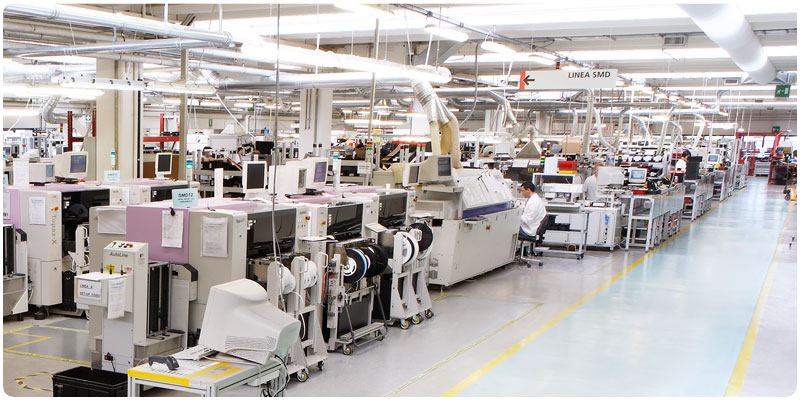

- Electronics and Hi-tech industries

- Evap. cooling for chillers and drycoolers

- Evaporative cooling for AHUs

- Hospitals and Operating Rooms

- Hotels

- Hypermarket

- Industry and Process

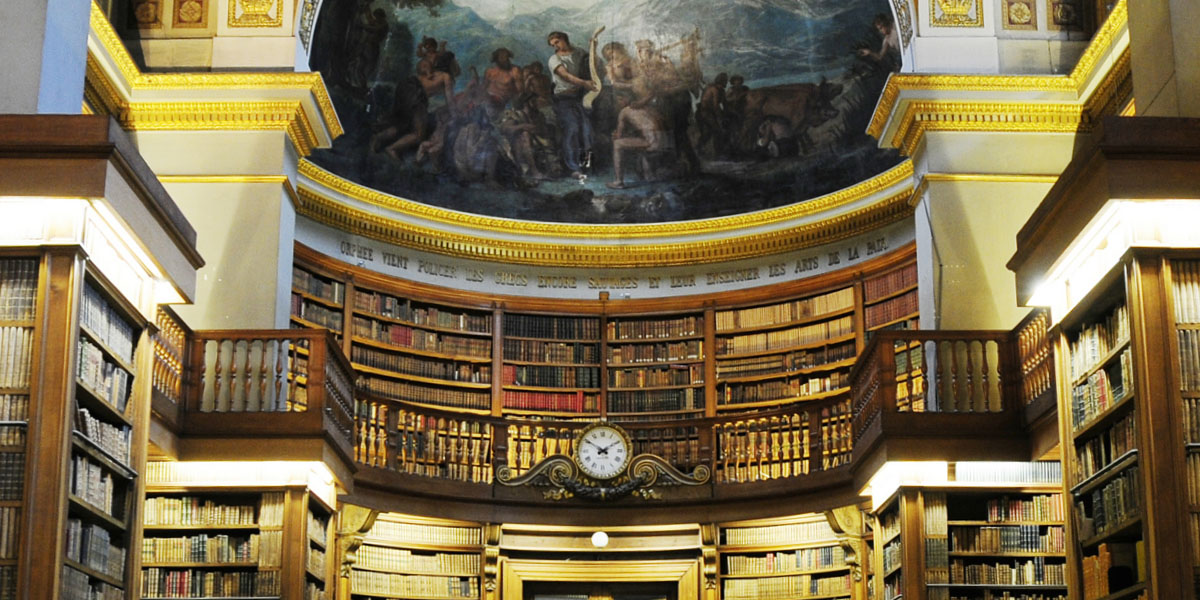

- Museums, Libraries and Theatres

- Offices

- Painting and coating

- Pharmaceutical industry

- Plastic Industry

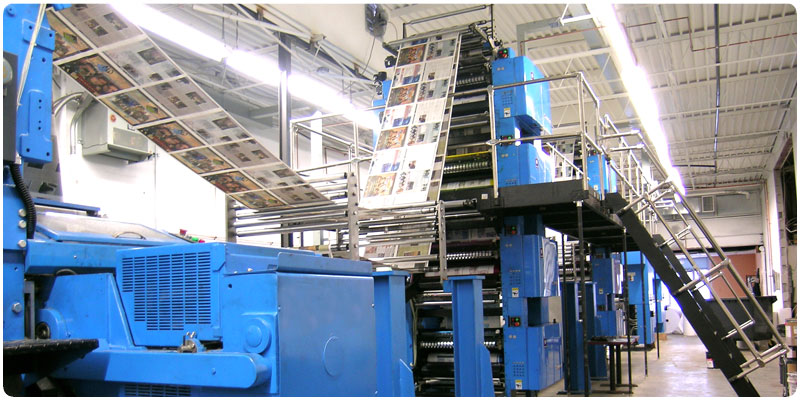

- Printing industry

- Production of bread and rusks (crisp bread)

- Remote operation centre

- Residential

- Restaurant chain

- Shopping centres

- Steam baths and Spas

- Textile industry

- Tobacco Industries

- Wine industry

- Wood industry

- Unit control

Plastic Industry

-

General characteristics

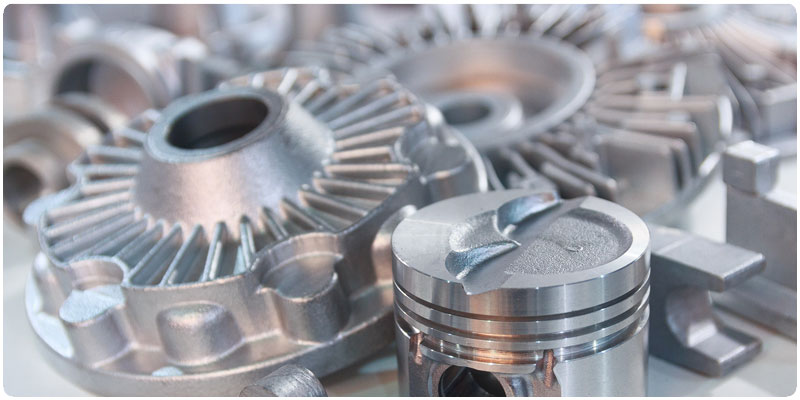

In plastic industry there are different ways to produce plastic parts: Injection molding, Blow molding, Thermoforming, Extrusion, etc…

In all of these manufacturing alternatives, precise temperature control of tooling equipment (i.e. screw thread sections where plastic flow, mould, etc..), is strategic for the process productivity and the quality of the finished product. A key role is then fulfilled by water chillers and Temperature Control Units (TCU’s).

Great impact of HVAC units is also in terms of energy efficiency, as cooling typically consumes 11% to 16% of the energy used in a plastics processing plant.

According to the type of plastic, mould temperature (5-220 °C) and melt temperature ranges (150-400°C) vary a lot, calling for flexible HVAC units with fast response and adjustable set-ups.

-

Discover related products

-

0 to 5 V ratiometric - SPKT*R* NA

-

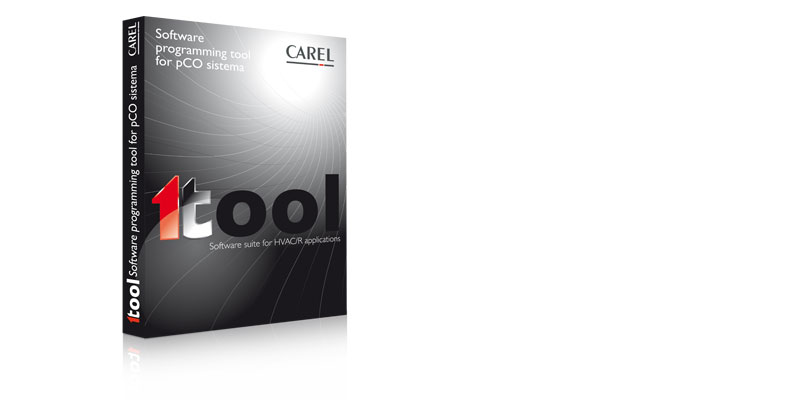

1tool

-

4 to 20 mA - SPKT*C*

-

Antifreeze thermostat

-

Bluetooth GATEWAY for apps

-

boss one

-

c.pCO

-

c.pCO mini

-

chillBooster

-

Clima

-

Cloudgate

-

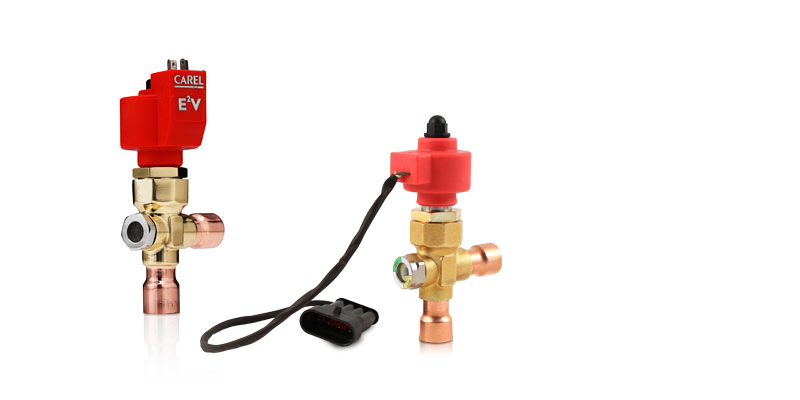

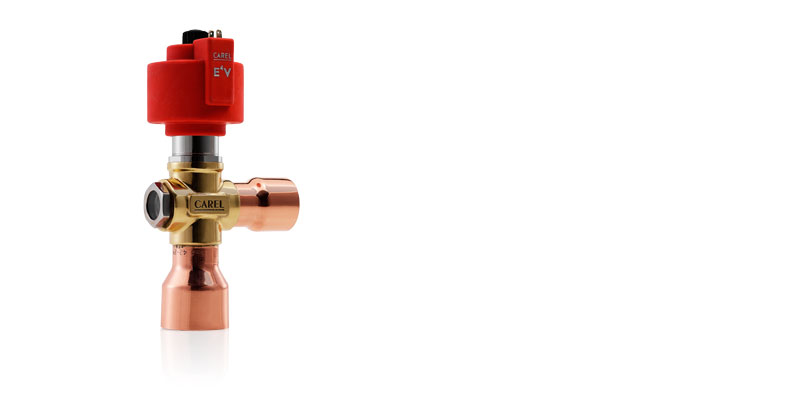

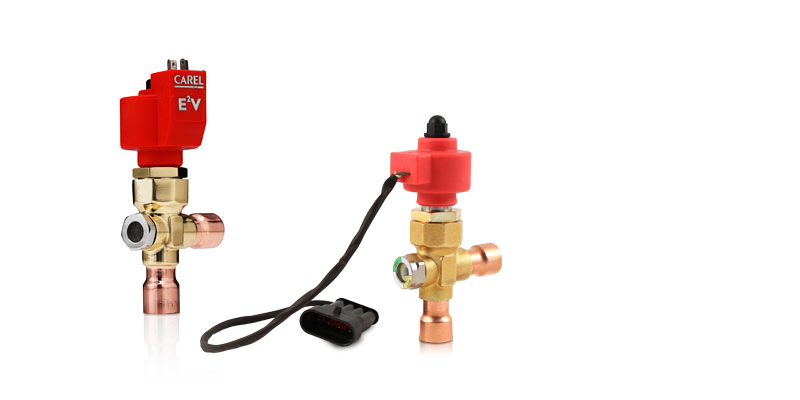

E2V - Z (demountable)

-

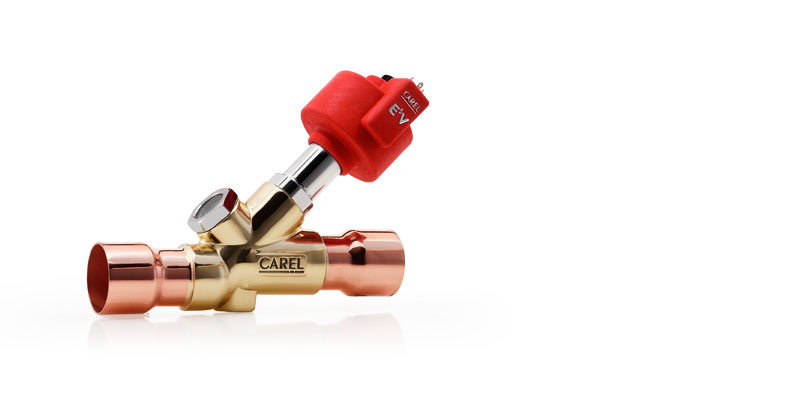

E2V fully welded

-

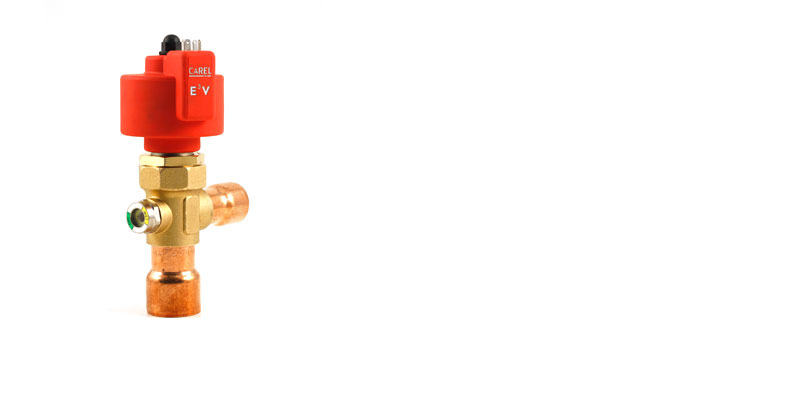

E3V - B (hermetic)

-

E3V - S (demountable)

-

E4V

-

E5V

-

E6V

-

E7V

-

easy way

-

EVD Evolution Twin

-

GLD Small

-

humiFog direct

-

ir33 universale

-

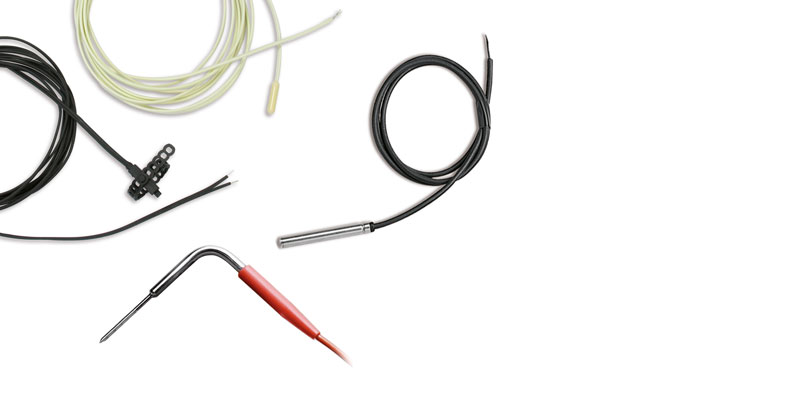

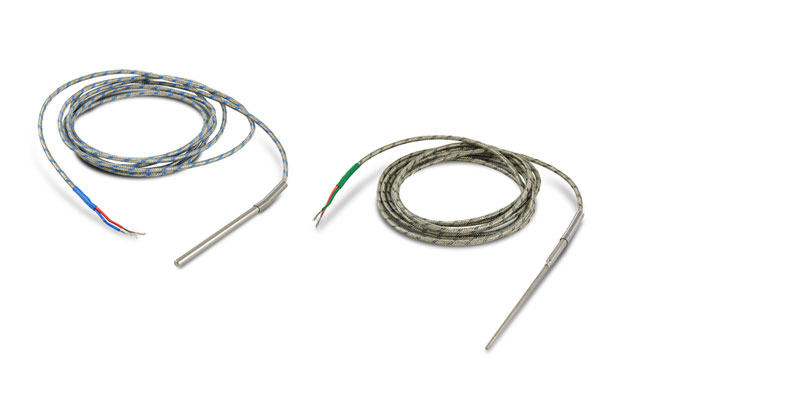

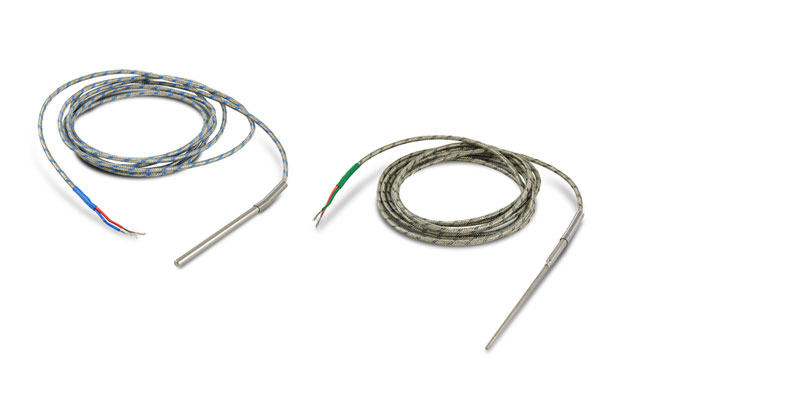

J and K thermocouples

-

k.air

-

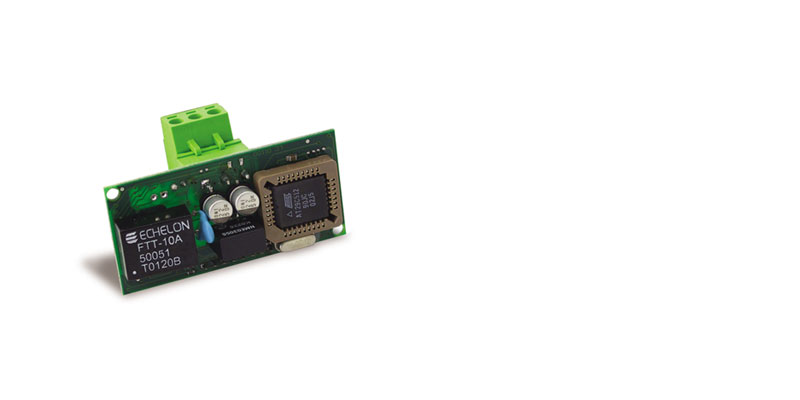

LONWORKS card NA

-

NTC

-

NXL variable frequency drive

-

pAD

-

pCO5+

-

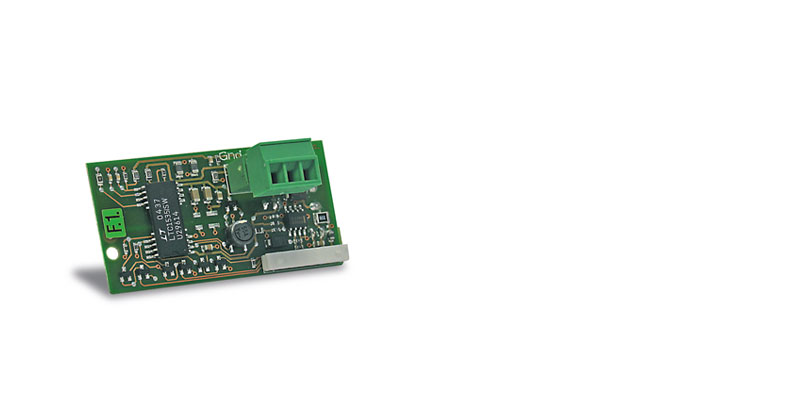

pCONet card

-

pCONet SE card

-

pCOWeb card

-

pCOWeb SE card

-

pGD Touch NA

-

pGD1 / pGDe

-

pGDX

-

Phase sequence controller (RSF)

-

PlantVisorPRO

-

PlantWatchPRO

-

pLDPRO

-

power+

-

PT1000

-

Ratiometric pressure sensors - SPKT*P0

-

Ratiometric pressure trasducers - SPKT*S0

-

Ratiometric trasducers welded version - SPKS*

-

RemotePRO

-

RS485 card

-

RS485 card- FieldBus

-

Series three-phase fan speed controller

-

single-phase

-

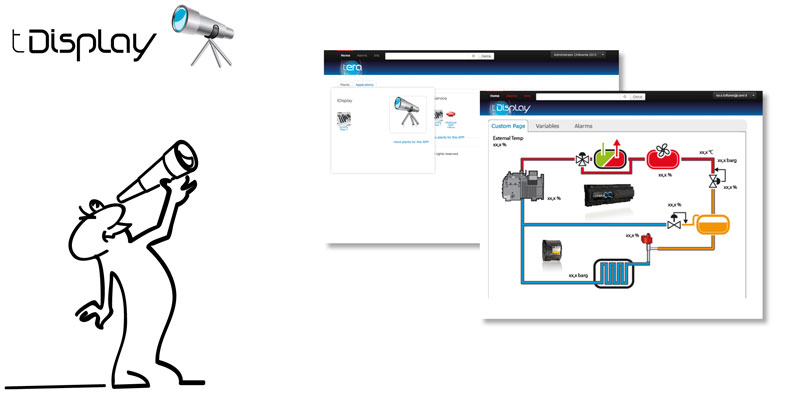

tDisplay

-

three-phase (IP55)

-

three-phase (IP55) with RS485

-

tService

-

Ultracap

-

Variable Frequency Drive

-

Wi-Fi GATEWAY for boss applications

-

µC2 SE NA

-

0 to 5 V ratiometric - SPKT*R* NA

-

1tool

-

4 to 20 mA - SPKT*C*

-

Antifreeze thermostat

-

Bluetooth GATEWAY for apps

-

boss one

-

c.pCO

-

c.pCO mini

-

chillBooster

-

Clima

-

Cloudgate

-

E2V - Z (demountable)

-

E2V fully welded

-

E3V - B (hermetic)

-

E3V - S (demountable)

-

E4V

-

E5V

-

E6V

-

E7V

-

easy way

-

EVD Evolution Twin

-

GLD Small

-

humiFog direct

-

ir33 universale

-

J and K thermocouples

-

k.air

-

LONWORKS card NA

-

NTC

-

NXL variable frequency drive

-

pAD

-

pCO5+

-

pCONet card

-

pCONet SE card

-

pCOWeb card

-

pCOWeb SE card

-

pGD Touch NA

-

pGD1 / pGDe

-

pGDX

-

Phase sequence controller (RSF)

-

PlantVisorPRO

-

PlantWatchPRO

-

pLDPRO

-

power+

-

PT1000

-

Ratiometric pressure sensors - SPKT*P0

-

Ratiometric pressure trasducers - SPKT*S0

-

Ratiometric trasducers welded version - SPKS*

-

RemotePRO

-

RS485 card

-

RS485 card- FieldBus

-

Series three-phase fan speed controller

-

single-phase

-

tDisplay

-

three-phase (IP55)

-

three-phase (IP55) with RS485

-

tService

-

Ultracap

-

Variable Frequency Drive

-

Wi-Fi GATEWAY for boss applications

-

µC2 SE NA

-

-

Discover related unit control applications