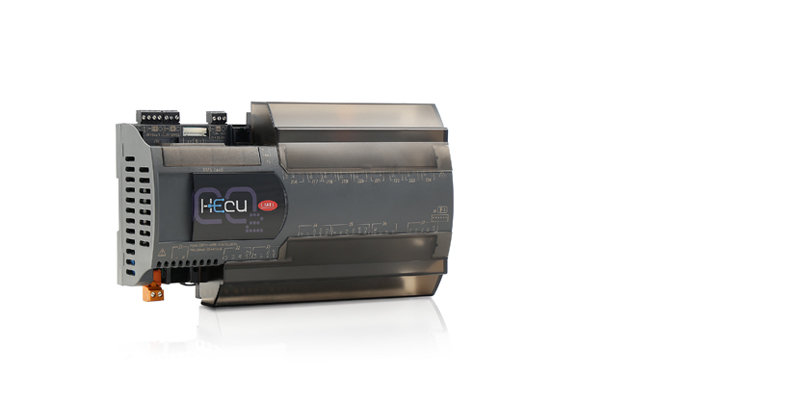

Hecu CO2

General characteristics

Hecu sistema has now evolved to work with natural refrigerants by integrating management of DC inverter compressors for CO2 refrigerant.

By using DC inverter compressors, Hecu sistema can offer real modulation of cooling capacity, so as to achieve low energy consumption above all at part loads. Such very high performance attainable with CO2 refrigerant means the system both complies with the Eco-design directive on energy performance and exceeds the limits set by the F-Gas Regulation for condensing unit applications.

Hecu sistema also stands out in the small plants for commercial refrigeration for its real-time communication with the refrigeration units, allowing implementation of advanced system optimisation logic, with dynamic set points and extremely stable control so as to ensure perfect food preservation and reduce food waste.

CAREL supervisors can be used to monitor and optimise the operation of all connected systems, preventing possible malfunctions and scheduling maintenance so as to guarantee excellent service levels.

-

Plus

New efficiency frontier

- Availability of DC inverter compressor for CO2 refrigerant

- Wide and real capacity modulation to maximize the efficiency at partial load

- Self-optimization through real communication with internal units

Innovation suitable for all

- System solution in a compact equipment fully integrated

- Intuitive programming and fast commissioning procedure

- Compact dimensions and weight, strong Total Cost of Ownership reduction

NO food waste

- Optimum envelope compressor management with a complete qualification process

- No down-time for oil return issue with advanced software feature and proper multisplit installation

- Stable product temperature thanks to modulating device and floating setpoint

Always connected

- Total connection with tERA system both GSM and Ethernet from all the devices

- Unit monitoring, settings management and periodical report for each plant

- Systems comparison and business intelligence tools within all units connected